Web handling is the science, engineering and equipment necessary to transport flexible materials, like paper, film, foil, textile and nonwoven (webs) through various converting processes, including laminating, slitting, coating, printing, metalizing, inspecting, drying and others. Proper web handling means delivering and conveying webs through these processes at maximum throughput with zero defects.

Web Handling Systems, Technology and Equipment

I want to touch on some key factors when it comes to Web handling. Please, understand this information just scratches the surface of web handling technology. It is meant as a brief guideline to give you a few things to keep an eye on to maintain proper web handling in most converting applications.

Volumes have been written and whole seminars have been devoted to each of these individual subjects. Google is a powerful tool to find some of this technical information. Additionally, if you need more information a good place to start is right here:

https://www.converteraccessory.com/whitepages/

https://www.converteraccessory.com/webinar/

https://www.converteraccessory.com/ss/index.php

Web tension:

Web tension is a transient force that effects your web in the machine direction, usually in three, separate tension zones. Keep in mind, you may have more than one of each zone in your machine, but each zone can be classified as unwind, internal (process) and rewind. Each tension zone is unique and can be controlled individually with its own tension value.

- Unwind tension zone has ever changing roll radius feeding into the converting process. The converting process wants to be fed the web from the unwind roll at a constant tension. However as roll radius decreases, tension will increase, unless torque output of the unwind brake is decreased at a linear rate relative to roll radius change.

Brake Torque Must Decrease to Keep Tension Constant When Unwinding

Automatic, closed-loop controls, like loadcell and dancer rollers can be designed to control tension in the unwind zone. Additionally, open-loop automatic tension controls, like ultrasound are an excellent, cost effective, simple replacement for manual torque (no tension control) control.

Web Tension Control Options

- Internal tension zone has no roll radius change and can be controlled with closed-loop loadcell or dancer roller controls.

- Rewind tension zone is just the opposite of unwind (above). Torque must be increased as roll radius grows.

Ultrasound for Unwind or Rewind Zone Control

However, you will need an open-loop tension control to sense roll radius to achieve TAPER tension. Most rewinds require some amount of taper tension. Taper tension gradually decreases tension in a rewound roll to help avoid crushed cores and starring of the inner rewound roll layers.

Web Guiding:

Lots of factors, including improper web tension control, webs with inherent camber (tight-side / loose-side), or misaligned machine rollers can cause webs to wander from side to side as they are being processed. We live in an imperfect world and converting machines are no exception.

Web guide systems are used to correct web position from unwind all the way through rewind. Old, outdated, obsolete web guide technology used a stream of air to sense edge position, and moved the web through hydraulic systems.

Today web guide technology utilizes much more efficient, accurate and stable, all-electric web guide systems. Check that all your web guide systems are operating properly. They should be operating smoothly without constant hunting (oscillation).

Investment in new, current web guide systems will provide fast ROI for almost any converting application.

Rollers:

Obviously, rollers route the web where it needs to flow through the converting machine. Rollers need to properly handle the web in order to prevent tension control issues, web guiding problems and most frequently, web wrinkle problems.

- Check roller alignment preferably with laser alignment equipment or available services. Remember, a web will seek to be perpendicular to a roller with which it has traction in its entry span to that roller. That means misaligned rollers will cause cross machine web movement and resultant web wrinkling.

Roller Options

- Make sure all idler rollers turn freely and they are turning synchronously with the web. In other words, the web itself is the drive belt for the idler roller. If webs are not in traction with rollers, web guiding and wrinkles will occur.

Check that Rollers Turn Freely on Their Bearings

- Check rubber coverings for wear.

- Make sure roller taper (roll face machining) is minimal. Roller taper will cause web walking and wrinkling.

Super Lightweight Carbon Fiber Roller

Anti-Wrinkle rollers:

When web wrinkles occur, invest in anti-wrinkle technology to prevent wrinkles before they become creases.

- Linear, smooth surface, anti-wrinkle rollers, like Double E Group’s WrinkleSTOP will eliminate 100% of web wrinkles with ZERO web distortion. WrinkleSTOP is Converting’s premier anti-wrinkle device which provides unparalleled ROI in almost any converting application.

WrinkleSTOP - Double E Group Premier Anti-wrinkle System

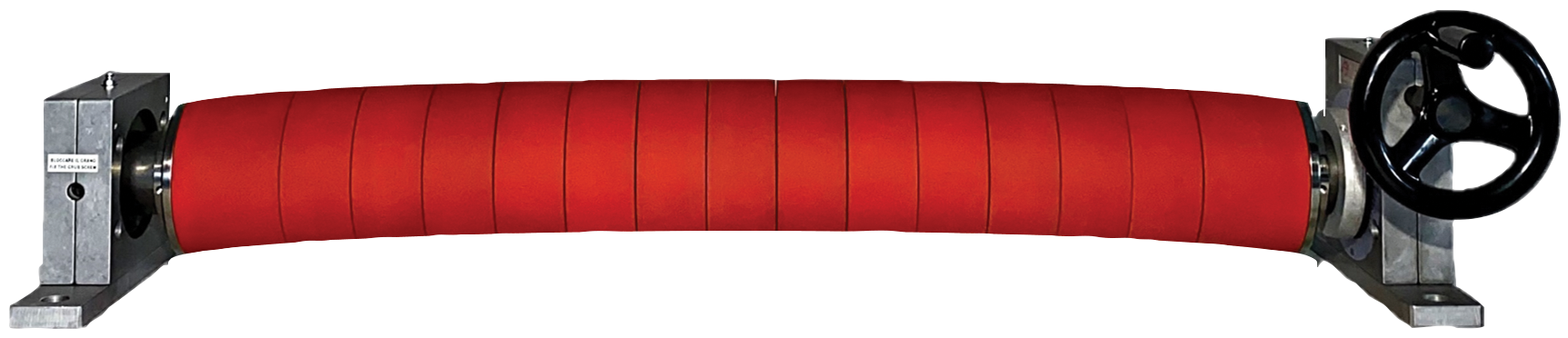

- Bowed rollers are viable anti-wrinkle and web spreaders in the right application.

Double E Group's Bowed Roller

- Double E Group’s Adjusta-Pull anti-wrinkle system is perfect for cost effective, immediate (usually in stock), aggressive (adjustable) anti-wrinkle system.

Adjusta-Pull Nip Type Anti-wrinkle system

Keep in mind, try to find a supplier with multiple tools in their anti-wrinkle toolbox. Don’t get roped into only one type of anti-wrinkle system because a specific supplier only offers one type.

Bottom line, if you look for ways to improve your web handling systems, your profits will increase by eliminating waste generated by web defects.

News No. 102

(800) 433-2413

(800) 433-2413

Please wait

Please wait