Description:

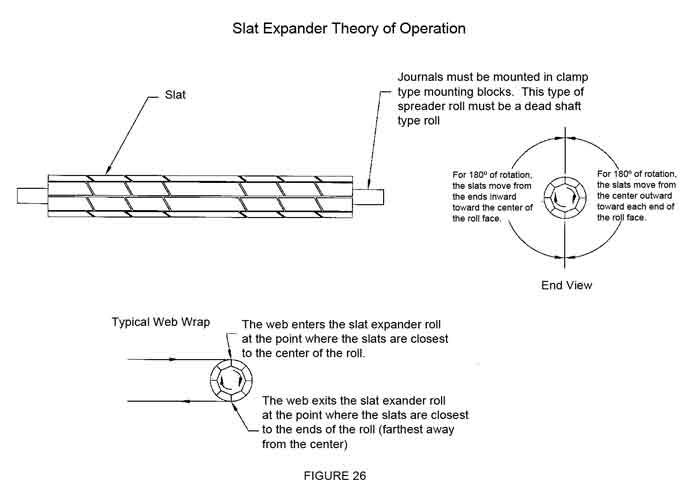

A Slat Expander spreader roll is manufactured with slats that move along the roll face as it rotates. The slats are manufactured from aluminum, steel or wood. The slats appear from the outside of the roll to be separate from each other.

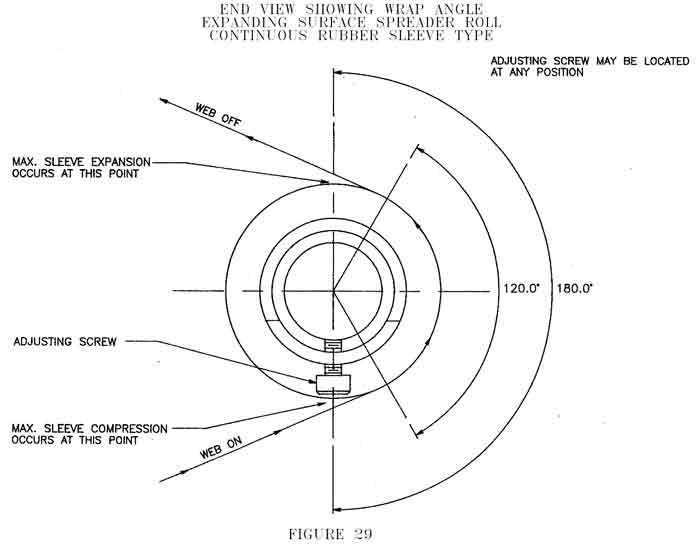

Theory of operation:

This roll has many slats that slide along the face from the center out to each roll end. The spreading occurs on the roll face as opposed to the entry span to the roll (as with other types of spreader rolls). The slats are engaged, mechanically, under the roll face and as this roll is driven (usually by the web, as an idler), the slats are mechanically pushed from the center to each roll end for 180° of rotation. For the next 180° of rotation, the slats move back toward the center of the roll. The web enters the roll face where the slats are closest to the center and exits where the slats are farthest from the center (closest to the roll ends). As the slats move toward the roll ends, under the surface of the web, wrinkles are removed. See figure 26.

Recommended wrap angle for this roll is from 90° to 180°. More wrap (up to 180º maximum) means more spreading. The amount of spreading is directly proportional to the amount of wrap angle. In other words 180º of wrap will provide for 100% of possible spreading, 90º of wrap will provide 50% of possible spreading, 45º of wrap will provide 25% of possible spreading, etc. Lead-in and lead-out distances are not critical in the application of this type of spreading device.

Advantages:

- This type of spreader roll is an aggressive wrinkle removal device.

- This roll is linear across its face, so tension remains evenly distributed across its face.

- This roll will not permanently distort or tear the center or edges of a web.

- This roll is manufactured for use with mainly woven and non-woven webs.

Disadvantages:

- This roll does not have a smooth surface so many webs can be marked, scratched or deformed from the use of this roll.

- This roll can be a high maintenance device. It has many moving parts.

- The amount of spreading is not adjustable.

Expanding Surface Spreader Roll – Polymer Band Type

Description:

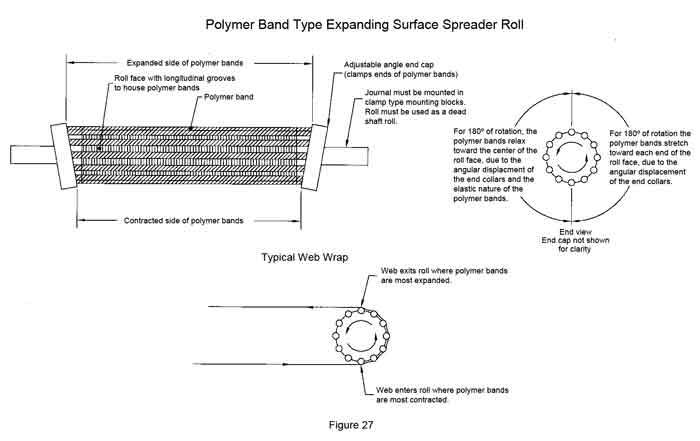

A Polymer Band Expander spreader roll is normally manufactured with an aluminum roll face. The roll face has longitudinal grooves cut below the surface in a shape corresponding to the shape of the polymer bands. Polymer bands are laid down into the grooves with their surface raised above the surface of the roll face. The ends of the polymer bands are clamped on each end with clamping end collars. The end collars are mounted on bearings, as is the roll face so they rotate together. The only thing connecting the roll face and the end collars are the polymer bands.

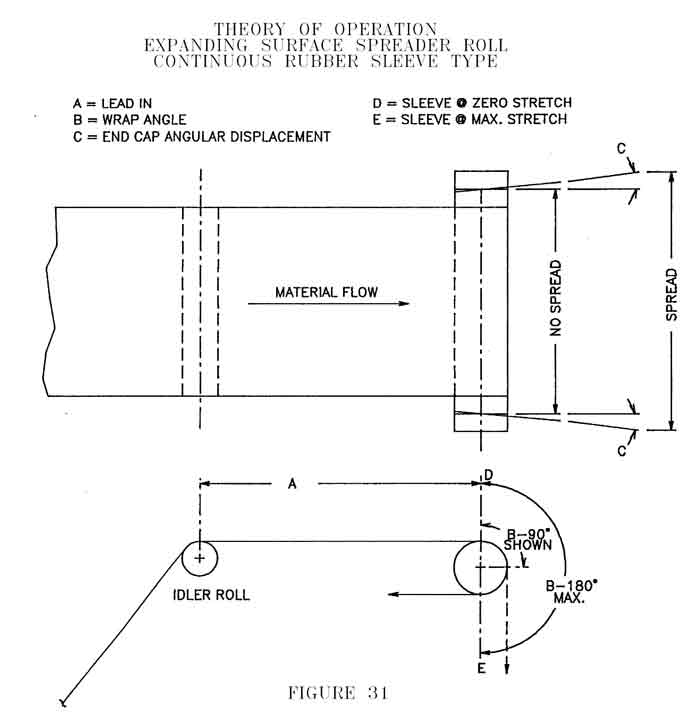

Theory of operation:

This roll must be mounted as a dead shaft idler or driven roll in order to operate properly. The clamping end collars, on each end of the roll face, clamp the ends of the polymer bands. The collars are mounted on bearing and axle assemblies, which allows the collars to be canted, relative to the axis of the roll face. The canting action is designed so the collars face in, toward each other, on one side of the roll face, and out, away from each other, on the opposite (180º) side of the roll face. As this roll rotates, the polymer bands expand for 180º of rotation, from the point where the end collars face toward each other to where they face away from each other. The polymer bands then contract for 180º of rotation, from the point where the end collars face away from each other to where the end collars face toward each other. The web must enter the roll in the 180º portion where the polymer bands are expanding and exit prior to the 180º portion where the polymer bands are contracting.

Recommended wrap angle for this roll is from 90º to 180º. More wrap (up to 180º maximum) means more spreading. The amount of spreading is directly proportional to the amount of wrap angle. In other words 180º of wrap will provide for 100% of possible spreading, 90º of wrap will provide 50% of possible spreading, 45º of wrap will provide 25% of possible spreading, etc. Lead-in and lead-out distances are not critical in the application of this type of spreading device.

Advantages:

- This type of spreader is an aggressive wrinkle removal device.

- This roll is linear across its face, so tension remains constant in the cross machine direction as the web travel over the roll face.

- This roll will not distort or tear the center or edges of a web.

- The amount of spreading is adjustable.

- This roll is used with all types of webs.

Disadvantages:

- This roll does not have a smooth surface so many webs can be marked, scratched or deformed from use of this roll.

- The raised surface of the polymer bands can cause wrinkles in the cross machine direction.

- The polymer bands are dynamic in their use, so they will wear over time.

Expanding surface Spreader Roll – Continuous Rubber Sleeve Type

Description:

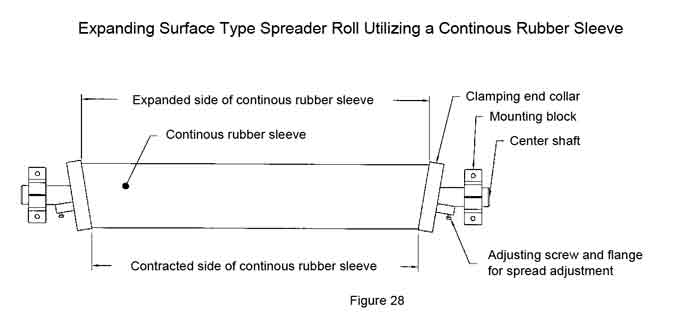

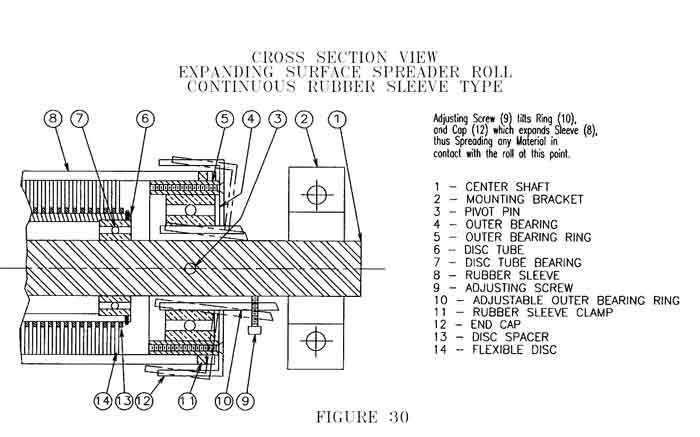

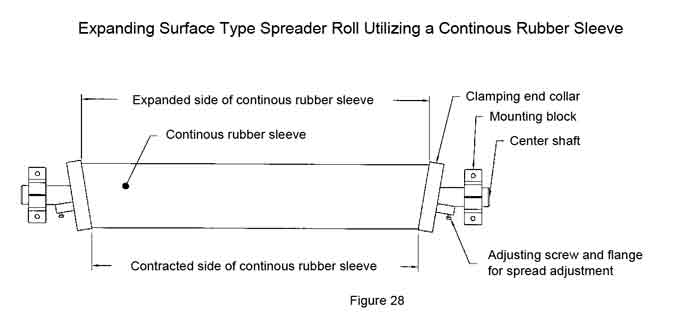

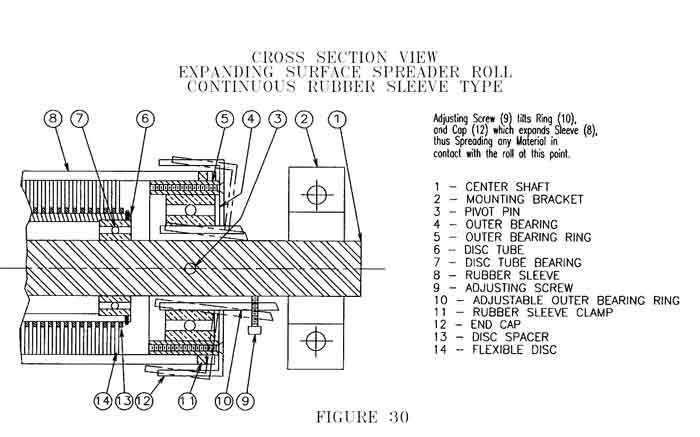

This type of spreader is manufactured with a rubber sleeve stretched across its face. On each end of the rubber sleeve there are end collars that clamp and hold the sleeve in place. The end collars are mounted on bearings and an adjustable axle. The sleeve is mounted across a series of flexible rubber disks. The rubber sleeve and end caps rotate together.

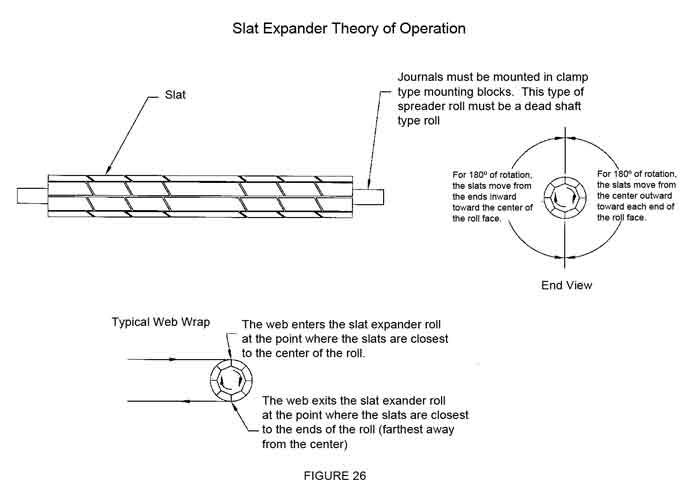

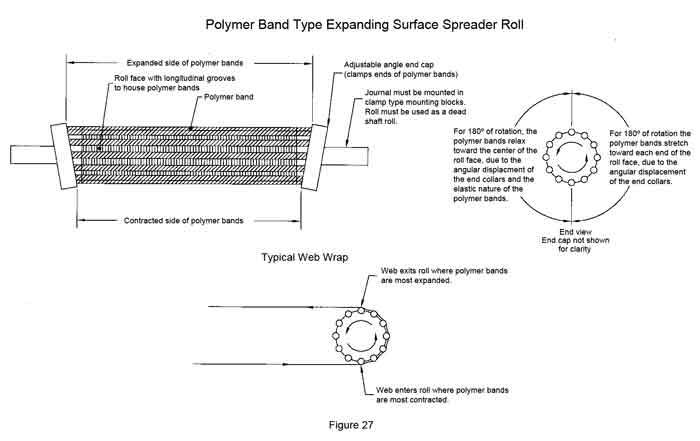

Theory of operation:

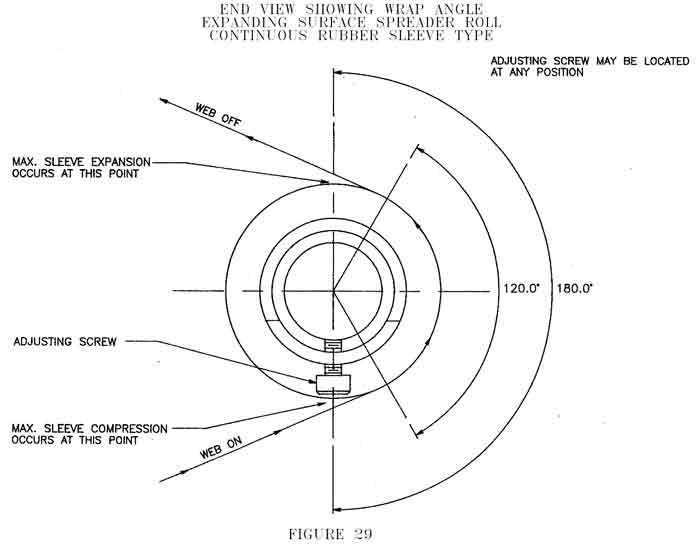

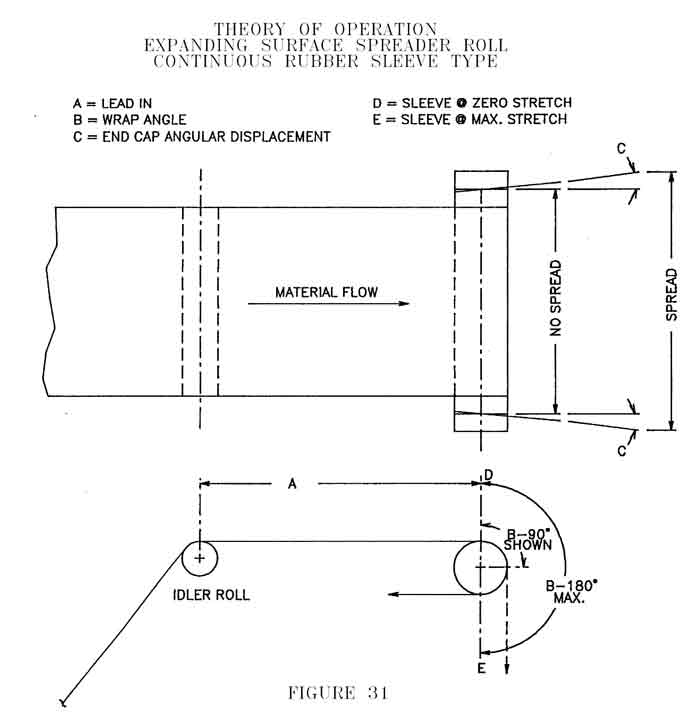

This roll must be incorporated as a dead shaft idler roll, in order to operate properly. The continuous rubber sleeve is pre-loaded across the face of the roll. The end collars are clamped on to each end of the rubber sleeve. The end collars are then canted with an adjustment screw and flange-axle assembly. The canting adjustment is designed so that the collars are facing each other on one side of the roll face and they are away from each other on the opposite (180º) side of the roll. The continuous rubber sleeve stretches from the point where the collars are facing each other, to where the collars are away from each other. The sleeve then contracts for the next 180º of rotation, from where the end collars are facing away from each other to where they are facing toward each other. Bottom line, the rubber sleeve physically stretches from the short side of the rubber sleeve to the long side of the rubber sleeve, then contracts again. The web enters the contracted side of the rubber sleeve and exits on the expanded side. As this roll rotates, the stretching action of the rubber sleeve spreads the web. See figure 28-31.

Recommended wrap angle for this roll is from 90º to 180º. More wrap (up to 180º maximum) means more spreading. The amount of spreading is directly proportional to the amount of wrap angle. In other words 180º of wrap will provide for 100% of possible spreading, 90º of wrap will provide 50% of possible spreading, 45º of wrap will provide 25% of possible spreading, etc. Lead-in and lead-out distances are not critical in the application of this type of spreading device, because all or most of the web spreading is taking place on the roll face, not in the entry span to the roll.

Advantages:

- This type of spreader is an aggressive wrinkle removal device.

- Spreading amount is adjustable from 0% (no spreading) - 100%.

- Spread adjustment can be made from each end of the roll, independent of each other, while the machine is running and with standard tools.

- This roll is linear across its face, so tension remains evenly distributed across the roll face.

- This roll will not distort or tear the center or edges of a web.

- It is available with a multitude of different sleeve compounds including abrasion, chemical and heat resistance and release for adhesive applications.

- Roll surface is smooth and linear so it will not mark, scratch or deform a web.

- This roll is used with all types of webs.

Disadvantages:

- Web speeds are a consideration when utilizing this roll. If the web speed causes the sleeve to balloon, as a result of centrifugal force, then the effect on web may be reduced.

- The sleeve is stretching and contracting with every revolution, so the continuous rubber sleeve will degrade over time.

- Although spreading does occur across the full width of the roll face, most of the spreading occurs toward the ends of the roll face, so the amounts of spreading are not even in measured increments across the face of this roll.

Jeffrey Damour, Sales Engineer, Converter Accessory Corporation

Wind Gap, PA, Phone 800-433-2413

|