This is a continuing article, discussing why wrinkles occur in webs. Review past articles for more tips on what to look for when your web wrinkles.

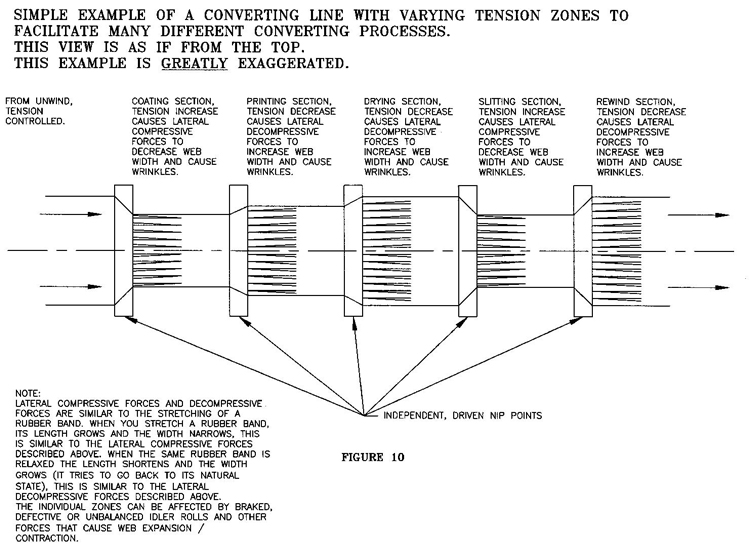

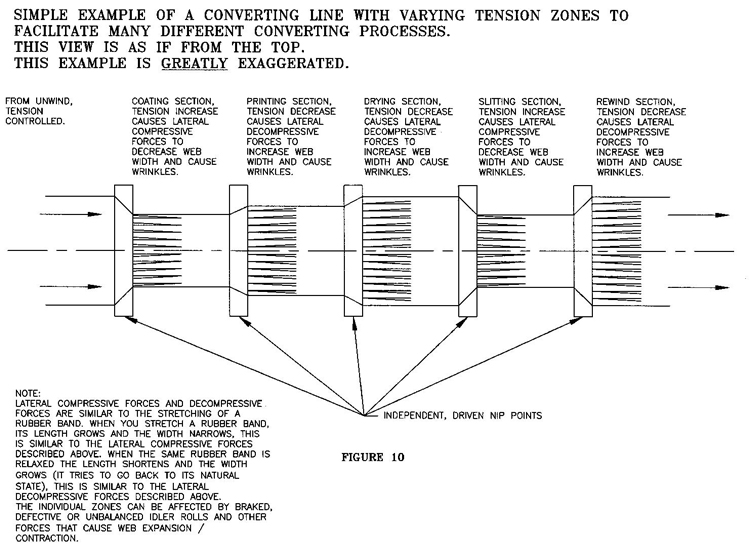

- Varying tension through several different types of processes in one converting line (figure 10) will cause wrinkles. A good example of this is tension through a coating section, printing process, drying section and slitting section. Tension through the coating section may be high, then through the printing process may be lower, then through the drying process lower yet, then through the slitting section may be high again. Wrinkles will occur under these conditions because the web will stretch and contract creating compressive and decompressive forces. Lateral (cross machine direction) compressive forces are created in the web because of a high tension. Decompressive forces are created from the web trying to return to its natural state after leaving a high-tension section. These lateral compressive and decompressive forces are very similar to stretching and relaxing a rubber band. When you stretch a rubber band, its length grows and its width narrows (lateral compressive forces make the rubber band narrow). When the same rubber band is relaxed, the length shortens and the width grows as it tries to return to its natural state (lateral decompressive forces). These individual tension sections (zones) can be affected by braked, defective or unbalanced idler or driven rolls that will create tension variations as the web is flowing through the process.

- A braked roller, defective roller or a defective bearing in an idler roller, will cause tension to vary on the downstream side of the idler roll. This will vary tension very similar to the situation described above. Again, as tensions vary, the web will stretch and contract creating wrinkles.

- Other web expansion and contraction effects on the web will create wrinkles. Examples of these effects are heat on plastics and moisture in paper.

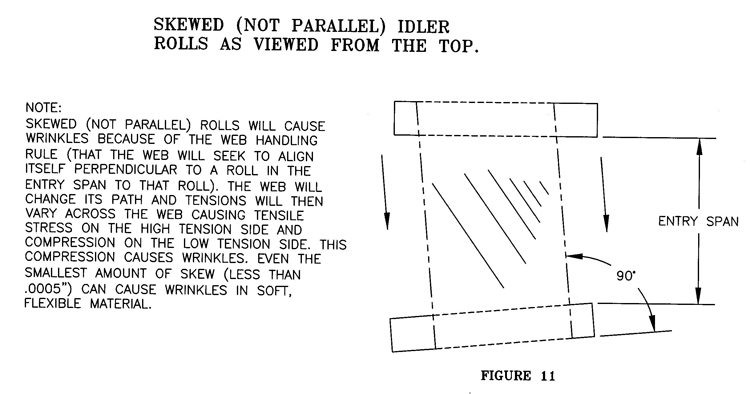

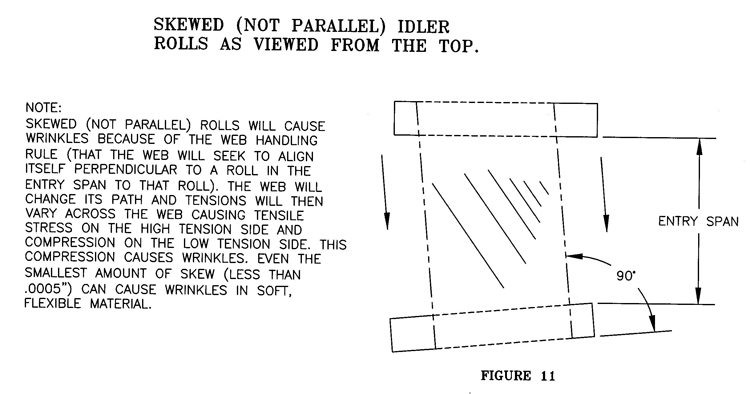

- If idler rolls and/or driven rolls are not parallel to each other (figure 11), wrinkles will occur. These occurrences are again introduced because of the web handling principal, that a web will seek to align itself perpendicular to a roll in the entry span to that roll. As the web is seeking this right angle it will move or bend out of its normal running plane. This will create tension to variations across the web, tensile stress in high tension area and lateral compression in the low tension

Future articles will discuss ways to combat web wrinkles.

Jeff Damour Converter Accessory Corporation800-433-2413

|