|

Core Support System |

New Cost-Effective Air Chuck is Designed for Demanding Applications

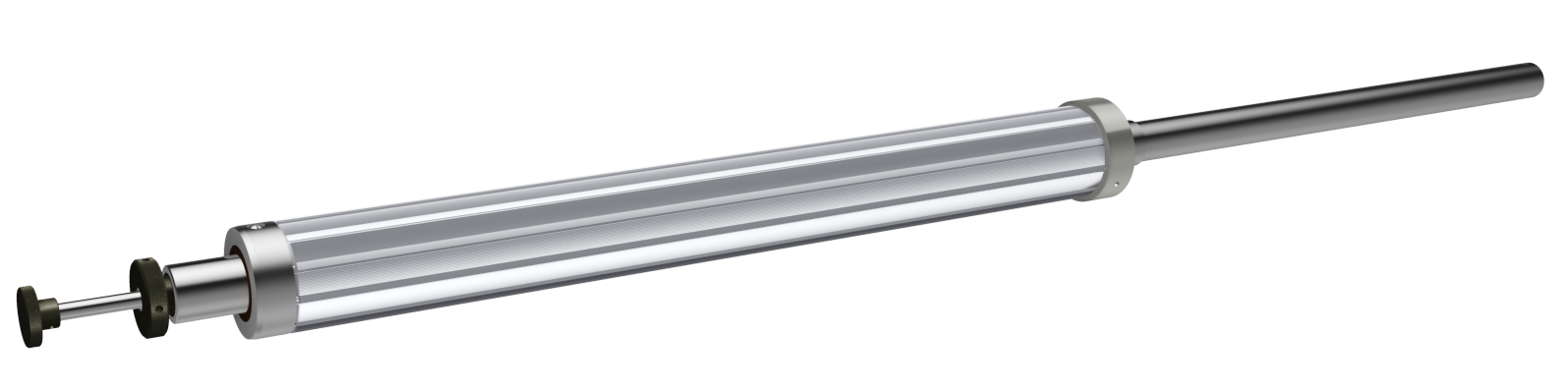

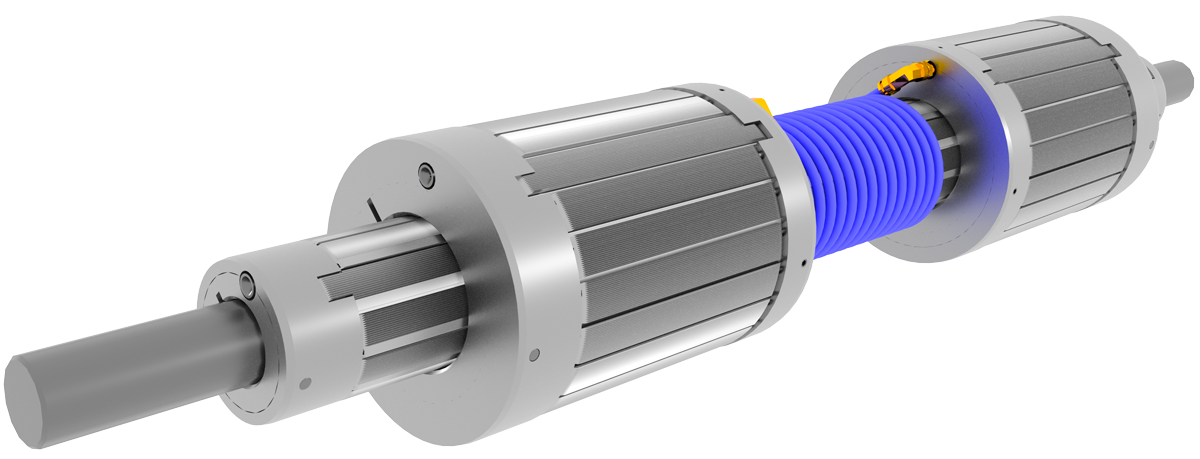

CAC® (Converter Accessory Corporation) adds a new, uniquely designed air chuck to its proven line of COR-LOK® air and mechanical chucks. This new COR-LOK-XE® model air chuck utilizes a pneumatically expanding, spirally wrapped external element to engage the core. These chucks are available for 2" - 18" diameter cores and use split bushings to lock to thru shafts for fast and easy placement and installation.

According to Jeff Damour, CAC's engineering manager, COR-LOK-XE® pneumatic chucks are effective with virtually all types of cores in light to heavy duty applications. CAC's unique split bushing design clamps and releases quickly and easily, holding the COR-LOK-XE® model chuck securely in place and will not mark or damage the thru shaft to which it is mounted.

CAC's® new COR-LOK-XE® model air chucks offer our customers a cost effective, simple answer to demanding applications where effective core holding is required. They are designed with standard, universal parts, so no matter what diameter air chucks our customers use; all parts remain consistent for all sizes. These chucks are designed to last with extremely limited maintenance. However, when maintenance is required, it is done with standard, stocked parts in less than 15 minutes.® Damour said.

COR-LOK-XE® pneumatic chucks feature a tubing (bladderless) design, contoured to match the geometry of the company's unique, spiraled shaft body. The contoured tubing allows exceptional, even gripping torque across the full length of the chuck, an extremely long tubing life and easy replacement. To inflate, they only require 70 PSI and can easily handle up to 120 PSI. COR-LOK-XE® air chucks feature unique, wear resistant external element locking system and ensure zero core damage. All models are lightweight and designed for easy, safe operation.

New Core Adapters Offers Cost Effective, Simple Answer

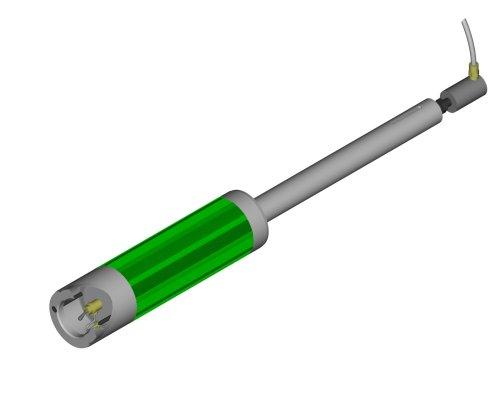

CAC (Converter Accessory Corporation) is offering new core adapters with the company's proven COR-LOK® core support technologies. The system uses sleeve based technology featuring CAC's unique split bushing locking design. COR-LOK® core adapters operate to handle core sizes from 2 up to 18 inches in diameter (3 and 6 inch being the most popular).

According to Jeff Damour, CAC's engineering manager, COR-LOK® core adapters are effective with virtually all types of air shafts and thru shafts. CAC's unique split bushing design clamps and releases quickly and easily. It holds the core adapter securely in place and will not mark or damage the air shaft or thru shaft support.

"CAC's new COR-LOK® core adapters offer our customers a cost effective, simple answer to a potentially difficult problem. When the need arises to run larger core diameters than a particular unwind or rewind setup can handle, CAC COR-LOK® core adapters can be used to effectively handle those larger cores." Damour said.

These new core adapters are covered in CAC's new COR-LOK® Core Adapters brochure and on CAC's website on the Core Adapters page. Contact us at 800-433-2413 to receive the brochure.

COR-LOK® pneumatic shafts, chucks and core adapters feature a tubing (bladderless) design, contoured to match the geometry of the company's unique, spiraled shaft body. The contoured tubing allows exceptional, even gripping torque across the full length of the core, a extremely long tubing life and easy replacement. COR-LOK® systems also offer several air valve options intended to match any application requirement. To inflate, they only require 70 PSI and can easily handle up to 120 PSI. COR-LOK® air shafts, chucks and core adapters feature unique, wear resistant aluminum leaf locking system and ensure zero core damage. All models are lightweight and designed for easy, safe operation.

New Lateral Adjust Option Allows Air Shaft Adjustment on the Fly

Converter Accessory Corporation (CAC®) is introducing a lateral adjust option with its COR-LOK® air shafts for cantilevered installations in narrow web applications.

The lateral adjust option is built into the air shaft and an easily and safely operated handwheel facilitates side to side +/- 4 inch adjustments while the machine is running and production continues. The system includes CAC's exclusive adjustable core stop flange. The air shaft can be inflated through a rotary union via CAC's patented remote toggle valve, or with an air gun.

COR-LOK air shafts with the lateral adjust option feature all the standard engineering features of the standard COR-LOK systems, including a tubing (bladder) design contoured to match the geometry of the company's unique, spiraled shaft body. All COR-LOK air shafts and chucks offer exceptional gripping power over the full core length; feature a unique, wear resistant aluminum leaf locking system, and ensure core protection and damage free operation. They are lightweight and carefully designed for easy, safe operation.

Additionally, lateral adjust COR-LOK systems are easily cleaned and are designed for use in food-grade operations.

Lateral adjust COR-LOK air shafts are available in 2 to 12 inch standard diameters and are capable of handling 500 lbs at speeds to 2000 feet per minute.

According to CAC General Manager Pamela A. DiFrancesca, lateral adjust COR-LOK air shafts address growing market demands for systems that facilitate continuous production and reduce down time.

”Every component of all COR-LOK shafts and chucks, right down to the standardization of air tubing, is aimed at minimizing down time. The lateral adjust system allows narrow web converters to make changes on the fly,“ Damour said ”and offers a production advantage that could prove significant in highly competitive markets.“

Founded in 1974, Converter Accessory Corporation designs, engineers and manufactures web handling equipment for converters of paper, film, foil, nonwovens and textiles. Engineered solutions include high quality, cost effective equipment from the simplest aluminum core cone to the most sophisticated unwind/rewind system. CAC is represented by knowledgeable sales engineers and provides extensive consultation and post sales support.

For more information contact Pam DiFrancesca, Converter Accessory Corporation, 201 Alpha Road, Wind Gap, PA 18091-1279, (800) 433-2413, fax (610) 863-7818. sales@converteraccessory.com Web site: www.converteraccessory.com

New On Shaft Inflation Toggle Valve Air Shaft Makes Roll Changes More Efficient

Converter Accessory Corporation (CAC®) is introducing a patented new inflation toggle valve COR-LOK® air shaft option, toggle valve COR-LOK air shaft, that helps reduce roll changeover times. Toggle valve COR-LOK air shaft employs standard rotary union for pneumatic hook-up and is specifically engineered for use in cantilevered applications. It is available in COR-LOK air shafts in 2 to 18 inch diameters.

According to Jeff Damour, CAC engineering manager, the main advantage of the toggle valve COR-LOK air shaft is that it facilitates rapid roll changeovers. Since the easily reached toggle valve is built into the end of the air shaft, an operator does not have to leave the station to access a remote inflation control or retrieve any tools.

”The toggle valve COR-LOK air shaft is a simple design that makes an exceptional contribution to efficiency," Damour said. "This option is well designed for use with label presses and is available in stainless steel for washdowns in food grade applications and offers all the advantages of our other COR-LOK air shafts.“

The toggle valve COR-LOK air shaft system is also compatible with CAC's sleeve-based core adapting option that allows converters to run varying core sizes, both 3“ and 6“ for example, on the same shaft or air shaft. This option allows rapid changeovers between rolls with differing core diameters ranging from 3 to 18 inches. CAC's sleeve-based core adapting system is especially effective in label production and other narrow web operations. It offers converters the additional economical option of employing two short sleeves at each end of the shaft rather than a single, longer sleeve to adapt varying core sizes.

The most recent COR-LOK air shafts and chucks feature a freshly engineered tubing (bladder) design contoured to match the geometry of the company's unique, spiraled shaft body. Compared to previous designs, the economical new contoured tubing allows increased gripping power, a longer tubing life and exceptionally easy replacement. The new COR-LOK air shaft and chuck systems also offer several air valve options intended to match virtually any plant requirements. To fully inflate, they require only 90 to 120 PSI.

COR-LOK tubing is unique in that it can be quickly and easily sized, on site, to match any CAC air shaft or chuck. Tubing lengths can be ordered in advance and stocked, thus minimizing down time, even in plants where a large diversity of air shafts and chuck sizes exists. To facilitate easy changeovers, the tubing is mechanically fixed, rather than vulcanized, to the air valve.

All COR-LOK air shafts and chucks offer exceptional gripping power over the full core length; feature a unique, wear resistant aluminum leaf locking system, and ensure core protection and damage free operation. They are lightweight and carefully designed for easy, safe operation.

CAC hosts an online air shaft support center featured on www.handleyourweb.com offering detailed instruction for servicing air shafts from CAC and other manufacturers. The air shaft support center allows for online ordering of spare parts, including aluminum core cones, tubing, valves and valve cores.

In addition to detailed instruction, online chat is also available, but not required to access information. Currently celebrating its 40th year of success, Converter Accessory Corporation designs, engineers and manufactures web handling equipment for converters of paper, film, foil, nonwovens and textiles. Engineered solutions include high quality, cost effective equipment from the simplest aluminum core cone to the most sophisticated unwind/rewind system. CAC® is represented by knowledgeable sales engineers and provides extensive consultation and post sales support. For more information contact Pam Damour, Converter Accessory Corporation, 201 Alpha Road, Wind Gap, PA 18091-1279, (800) 433-2413, fax (610) 863-7818. cac@epix.netNonwovens Producer Turns to Single Source for Two Effective Upgrades

Trenton, South Carolina: Bondex, a Trenton, South Carolina manufacturer of nonwovens, solved two nagging production problems with mechanical solutions from a single source, Converter Accessory Corporation (CAC).

The first problem was with an air shaft, button type design that clogged and became ineffective under production conditions.

According to Charlie Waters, Bondex Production Manager, Bondex's nonwovens production was plagued by frequent disruption when material; fibers and dust, from roll cores built up in and then clogged the button type air bladder openings. Not only did this accelerate wear on the bladders, but also, as the openings became clogged, prevented firm, uniform contact between the buttons and the cores. Operation of the air shaft became ineffective, production had to be shut down and the air shafts serviced. Frequently, the bladders in the button type air shafts were too difficult to replace in house and had to be sent to the manufacturer for refitting.

For Waters, the amount of downtime caused by air shaft failures was unacceptable. When salesman John Burch from Louis P. Batson Company, a Converter Accessory Corporation (CAC) agent, presented COR-LOK air shafts as an alternative, Waters was intrigued enough to give one a trial.

Unlike button-type systems, COR-LOK air shafts and chucks feature a tubing design contoured to match the geometry of its unique, spiraled shaft body. These inflatable tubes are able to match and usually exceed the gripping power of other systems, including button-type. Importantly, so far as Waters was concerned, CAC's COR-LOK air shafts offer exceptionally easy maintenance and tube replacement.

CAC's tubing fits all CAC air shafts and chucks. It can be ordered and stocked in advance and cut to length, on site, to match any COR-LOK air shaft. This feature is especially important in a facility using a diversity of air shaft and chuck sizes. The tubing itself is mechanically fixed to the air valve rather than vulcanized, and thus can be easily replaced by virtually any operator using simple hand tools. The tubing requires only 60 to 120 psi to fully inflate.

After the first COR-LOK air shaft was installed and tested on Bondex's nonwovens production line, the results were so impressive that Waters decided to replace the remaining button-type systems with the CAC technology.

The second production problem, less urgent but none-the-less a stewing annoyance in the background, was with a venturi trim removal system that sometimes clogged, was limited in how far it blew waste, and too limited in the volume of trim it could handle.

Burch said he had a solution to the trim removal annoyance as well and introduced Bondex's Waters to CAC's Fox TrimAway ®venturi and blower based trim removal system. CAC offers 30 standard systems with blowers from 1 HP to 15 HP. All components are engineered to match each customer's specifications. Components include a unique, adjustable venturi, regenerative blower, pickup nozzle, Y connectors, collection centers, flexible ducts, motor starters, trim choppers, filters and silencers(if needed); it is a complete, ready-to-work trim removal system fully supported by readily available spare parts. ”Since we liked the air shaft and were impressed with the sensible engineering behind it, we were pleased to find the same common sense approach in the Fox TrimAway.“ Waters said. Waters says the FOX TrimAway runs quieter, handles more trim and heavier trim, sends it farther and is more reliable than the system Bondex had before. ”I don't think it ever clogs,“ Waters said. Finally, Waters said, ”We really appreciate the efficient, cost effective design engineering behind both these systems. They install easily. They run like they're supposed to and you can service them yourself, in house, with your own people. Can't beat that.“Core Holding Options

If you unwind and rewind rolls of material, you most likely must decide on the best type of core holding for your converting operation. That is, how you hold the core of your material roll for unwinding or rewinding. There is a multitude of core holders from which to choose. Here are the most common types:

Air shaft – a deflated air shaft is inserted into a core. It is then inflated with compressed air to activate a core gripping mechanism.

Main Advantages:

· Easiest to use

· Works well for high tension (torque requirement) applications

· Good for heavy rolls

Main disadvantages:

· Most expensive

· Custom manufactured with longer lead-times

· Can be heavy for handling

Dual air chuck – dual air chucks are similar to air shafts but utilize two, short, independently inflated air chucks mounted on a thru shaft.

Main advantages:

· May be lighter weight than an air shaft

· Cost effective, usually stocked

· Easy to use

Main disadvantages:

· Must move air chucks for varying web widths

· Must be inflated independently (two places, instead of one)

· Less torque for lighter tension applications

Tandem air chuck – Tandem air chucks are similar to dual chucks but they can be inflated in one position because they use pneumatic tubing between chucks.

Main advantages:

· Air chuck advantages (above) but faster roll loading and unloading with one inflation point

· Less expensive than air shafts

· May be faster delivery than a custom air shaft

Main disadvantages:

· Must be moved in and out for varying web widths

· Less torque than air shafts

· More expensive than dual air chucks

Dual mechanical chucks – mechanical chucks lock cores in place without the use of air. They are very similar to their air chuck counterparts, but no air required.

Main advantages:

· No air required, may be useful for specific applications

· Some designs are “torque sensitive” meaning they work GREAT for HIGH torque applications where tension may be very high

· Cost effective

Main disadvantages:

· May be harder to load and unload than air chucks

· Core dust may affect operation

· Minor diameter to expanded diameter range does not allow for a lot of core size variance.

Chuck (air or mechanical) and end plug – This type of core holding arrangement can use air or mechanical chucks and a “dummy” end plug. The end plug is a cone shaped device that simply supports one end of the core while the chuck supports the opposite core end. The chuck delivers the torque to lock the core in place.

Main advantages:

· Cost effective

· Simple

· End plug includes a core stop flange for core alignment in the unwind or rewind

Main disadvantage:

· Half the torque output, compared to dual chucks

· Not well suited for wide widths, large diameter rolls and / or high web tension

Core cones – the simplest of all core holding methods. This system uses two cone shaped, serrated cones that are pressed into each core end to hold and lock the core in place.

Main advantages:

· Extremely cost effective

· Great for crushed cores

· Very simple to use

Main disadvantages:

· Least operator friendly

· Limited to certain core sizes

· Cone must be removed to load and unload

How to Get the Most From Your Leaf-Type Air Shafts

Air shafts are core support mechanisms that slide inside of a core of a roll or material. They serve as a coupling mechanism between your material roll core and a power transmission device like a brake on an unwind or a drive on a rewind.

Leaf type air shafts, like CAC's COR-LOK series air shafts, utilize an expanding element under leaves mounted around the circumference of the air shaft which move outward to engage a roll core. When air pressure is applied to the leaf type air shaft the expanding element expands under the air shaft leaves which actuates the leaves.

Things to consider when utilizing leaf type air shaft technology:

- Many leaf type air shafts are designed to be light weight. Take advantage of this feature to improve your ergonomics.

- Leaf type air shafts deliver lots of torque to your core so they are well suited for low to high tension applications.

- Zero core damage will occur with the use of this type of air shaft. So, if you re-use your cores, these air shafts are the perfect choice.

- Inflate this type of air shaft according to the manufacturers recommended air pressure to take advantage of their high torque capability. If the core slips on the leaves (due to improper inflation) leaf damage, due to unnecessary wear will occur.

- Leaf type air shafts, typically, do not have as much beam strength as their button type or lug type air shaft counterparts. Keep this in mind when supporting heavy rolls of material.

Leaf type air shafts are an excellent choice for holding unwind and rewind rolls. When properly applied they will provide years of light weight, reliable service.

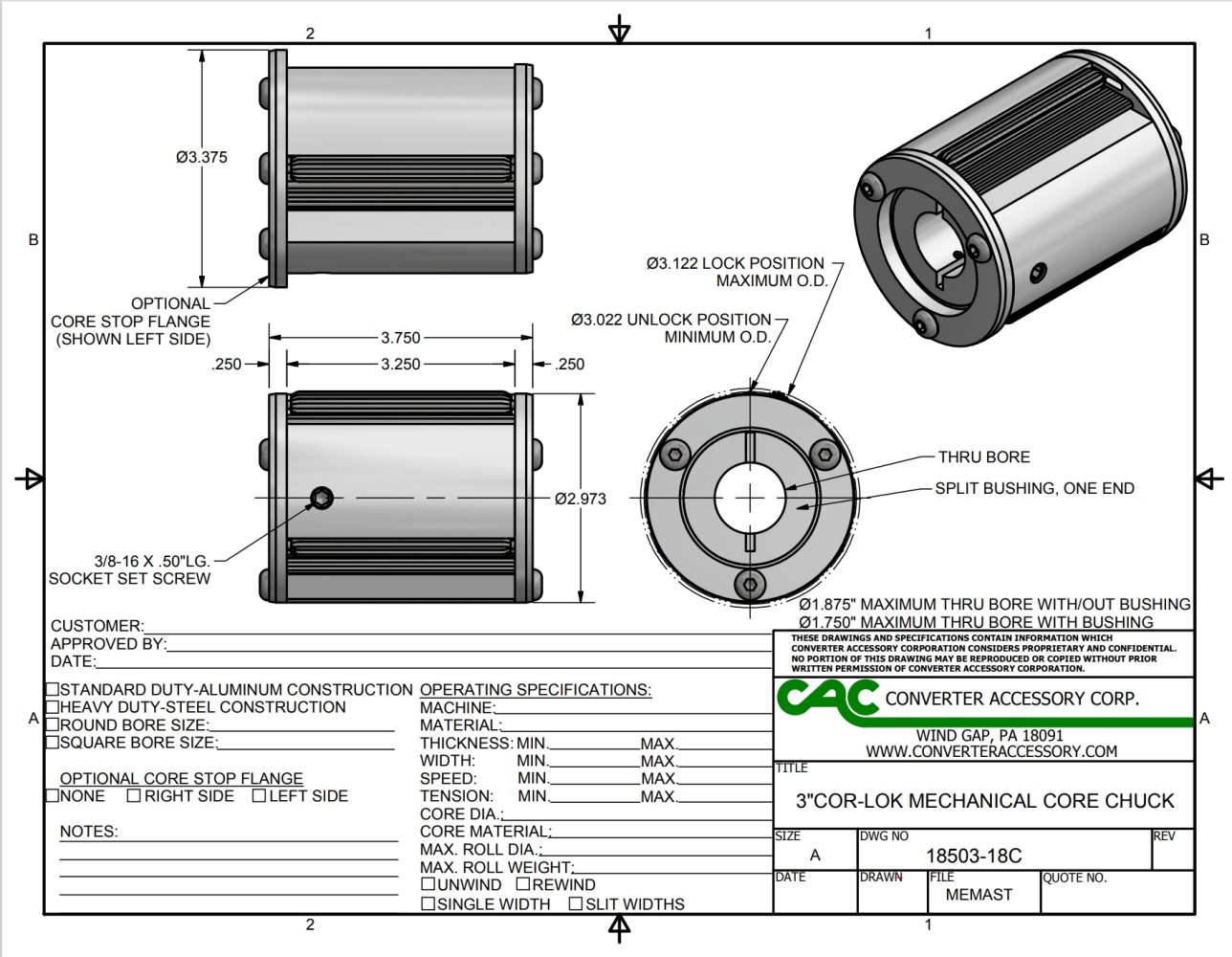

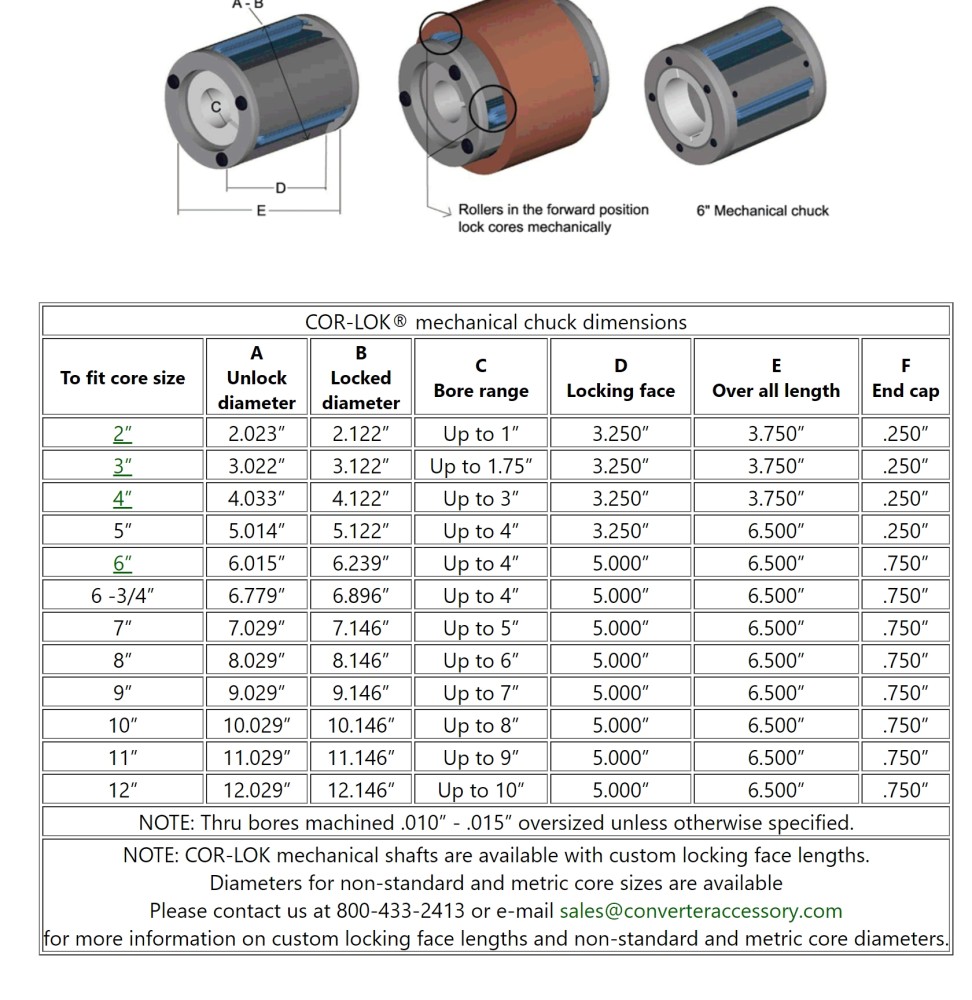

Get the Most from Your Mechanical Chucks

Mechanical Core Chucks

Mechanical core chucks are an excellent choice for holding the core of a roll of material. They work equally well for unwind and rewind applications. Mechanical core chucks operate mechanically without the need for compressed air (no inflating or deflating, as with air operated chucks). Oftentimes, they can deliver higher levels of torque than air operated core chucks. Mechanical core chucks can be more difficult and take more time to load and unload from the cores they support. Here are a couple of tips to get the most from your mechanical core chucks.

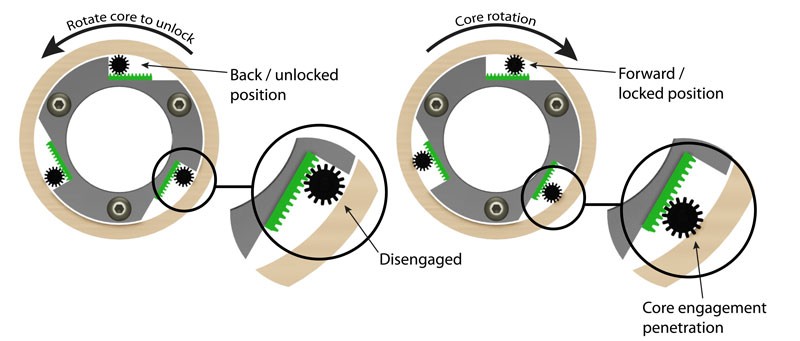

Consider how the mechanical core chucks are operated. Many mechanical core chucks lock "automatically" with the rotation of the core. If that is the case, then maintaining web tension is critical. It is web tension and the torque associated with it that actuates the core locking mechanism with this type of mechanical core chuck. If your web tension varies greatly or goes slack (throws a loop), as with some intermittent feed applications, for example, then the mechanical core chuck may lose grip of the core. Air chucks may be a better choice if your operation doesn't maintain tension under normal running conditions.

Auto-locking Mechanical Chucks

Do you need bi-directional locking? Some mechanical core chucks offer locking in one core rotation direction only and unlock in the opposite core rotation. Some mechanical core chucks will lock with either rotational direction and unlock in the middle of the travel between the two lock positions.

Maintenance can be an issue. Springs, gears and other parts will wear over time. Keep up with the maintenance of your mechanical core chucks. When considering new mechanical core chucks, remember simpler design means less maintenance and less components to fail.

Core material can be an issue. Mechanical core chucks work well with standard cardboard cores but may have trouble properly engaging plastic or metal cores.

Make sure mechanical core chucks are properly specified to handle your roll weight and tension (torque) requirements.

Necessary Operating Specs

Cores often vary inside diameter (I.D.) sizes. Be sure your mechanical core chuck expansion range; unlocked position to locked position will accommodate your core I.D. variance.

Dimensions

Are the mechanical core chucks being supplied with a thru bore to fit a thru shaft? If so, consider how the mechanical core chuck clamps to the thru shaft. Some designs use simple set screw, directly contacting the thru shaft. Better designs use other methods (like split bushing) of locking to the thru shaft for more positive locking without the possibility of damaging the thru shaft with set screw contact.

Finally, if your not the person who runs the machine, talk to the person who does. Discover their concerns when it comes to making easy, fast roll changes. Make sure the mechanical chuck you use is the best solution for the people who run the machine and make roll changes.

How to Get the Most from Your Cantilevered Core Holders

Unwinding and rewinding of narrow width, lighter rolls will, oftentimes, be accomplished using cantilevered core holders. Unwind and rewind stands, incorporating cantilevered core holders, feature faster and easier roll changes when compared to roll support methods with dual pedestal support. Here are some ways to get added value from your cantilevered core holding application:

1) Use air shafts to hold the core, so the roll of material will slide, easily, on and off for fast and easy roll changes. Leaf type air shafts are the most efficient with zero core distortion.

2) Cantilevered air shafts are available using rotary union connection to facilitate inflating and deflating. The inflate and deflate operation can be controlled with a simple remote mounted toggle valve or through HMI control. This eliminates the need for an inflating gun to inflate the air shaft, speeding up roll changes and lowering machine operator interaction.

3) Toggle valve operation can be built into the cantilevered end of the air shaft. This is the ultimate in ease of air shaft operation. This design has the toggle valve front and center when the operator makes roll changes. Allowing the easiest and fastest roll changes.

4) Cantilevered air shafts can be designed with built-in lateral adjust. Typically, these designs include facilitating the lateral adjustment, on the fly, while the machine is running. Manual lateral adjustment is handy when your operators want to position the web, laterally, in the machine without stopping to deflate the air shaft and reposition the roll. Bottom line, this modification can really speed up your overall setup process if lateral web position is a concern. This air shaft can be designed to utilize the standard inflating gun inflation method or the remote toggle valve inflation method.

If your application already utilizes cantilevered core holding, consider these options to get the most from the cantilevered design. If your unwind or rewind stand is currently dual pedestal (core holder supported on both sides) and you feel you would benefit from cantilevered core holding, consider the upgrade to cantilevered air shafts.

Air Shaft Deflection

In past articles we have discussed the benefits of cantilevered air shafts for use in unwinding and rewinding applications for ease of operation, loading and unloading. These air shafts are available with many different options, unique to cantilevering, again, these options have been discussed in previous articles. These added features make cantilevered air shafts even more attractive.

Cantilevered Air Shafts

Applications allowing cantilevered unwind and rewind air shafts are limited. The limiting factor being deflection. Since cantilevered shafts are supported on one side only, they deflect much more than their dual supported counterparts. The bearing support becomes a fulcrum point, so any minor deflection or movement at the bearing support can turn into a major amount of movement at the cantilevered end of the shaft.

When the air shaft deflects under the weight of the unwind or rewind roll, you are in effect, skewing the unwind or rewind roll to the rest of the rollers and processes in your machine. Just like any roller in your machine, your roll of material should be parallel and square to the rest of the rollers in the process. Skewed rolls and rollers can cause web handling problems such as misalignment and web wrinkles.

One consideration is how much deflection your web and process can actually accept before it becomes a problem. For example, if you are processing heavy sand paper, this type of web can typically allow much more deflection than a .0005" thick low density polyethylene. Other factors such as machine speed as it pertains to machine vibration can also come into play.

Cantilevered Unwind for 36" Wide Heavy Paper Application

Your cantilevered shafts must be designed with enough stiffness to limit deflection to allowable amounts for your application. And of course, bigger (diameter) is better - I know, an obvious statement, but one that should be mentioned. So first you must determine how much deflection at your unwind or rewind roll your process can accept and still produce acceptable end product. Then a calculation must be made relative to your roll weight, core diameter, roll width and support shaft or journal diameter to actually tell you what the approximate deflection may be.

To assist with estimating deflection, CAC has published several deflection calculators here: http://www.converteraccessory.com/ss/index.php. Now for the disclaimer - These calculators are meant only as a guideline. Each application should be reviewed under the scrutiny of a qualified engineer to validate actual conclusions.

Registration / Login Required

RETURN TO TOP |

Please wait

Please wait