Options for Core Holding | |

|

If you unwind and rewind rolls of material, you most likely must decide on the best type of core holding for your converting operation. That is, how you hold the core of your material roll for unwinding or rewinding. There is a multitude of core holders from which to choose. Here are the most common types: Air shaft - a deflated air shaft is inserted into a core. It is then inflated with compressed air to activate a core gripping mechanism. Main Advantages:

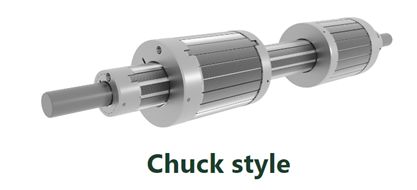

Dual air chuck - dual air chucks are similar to air shafts but utilize two, short, independently inflated air chucks mounted on a thru shaft.  Main advantages:

Tandem air chuck - Tandem air chucks are similar to dual chucks but they can be inflated in one position because they use pneumatic tubing between chucks.  Main advantages:

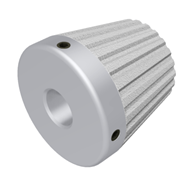

Dual mechanical chucks - mechanical chucks lock cores in place without the use of air. They are very similar to their air chuck counterparts, but no air required.  Main advantages:

Chuck (air or mechanical) and end plug - This type of core holding arrangement can use air or mechanical chucks and a "dummy" end plug. The end plug is a cone shaped device that simply supports one end of the core while the chuck supports the opposite core end. The chuck delivers the torque to lock the core in place.  Main advantages:

Core cones - the simplest of all core holding methods. This system uses two cone shaped, serrated cones that are pressed into each core end to hold and lock the core in place.  Main advantages:

Written By: Jeff Damour | |

|

**DISCLAIMER - A great deal of time has been invested in the development of our weekly tech tips. To the best of our knowledge, they are accurate. It is up to the user to verify all results. THE AUTHOR ASSUMES NO LIABILITY CONNECTED WITH THE USE OF THIS INFORMATION OR THE RESULTS OBTAINED FROM IT. | |